Headquarters

Glatten, Germany

Manual design of vacuum gripping systems has historically been time-consuming and specialized, resulting in inflexibility and generic solutions that fail to address the varied and changing requirements of automated industrial operations.

Leveraging trinckle's paramate cloud technology, J. Schmalz GmbH now delivers a revolutionary online platform for users to effortlessly design and order a 100% customized vacuum gripping system, optimized for their specific handling tasks.

With intuitive configuration, real-time CAD model generation, and the power of 3D printing, it's now possible to design a bespoke gripper ready in ten minutes, eliminating manual design costs and embracing the demand for tailored solutions in the era of automation.

Headquarters

Glatten, Germany

Industry

Automation machinery

Size

1500 +

Product

Custom solution

Manual design effort for each vacuum gripping system

Use of standard gripping systems: lack of flexibility

100% optimized for the individual handling task of the customer

Configuration in just ten minutes

No manual design costs

Customer integration within an intuitive configuration process

With an increasing degree of automation in industrial environments, plus constantly changing production processes, more and more individual handling tasks arise.

These dynamics challenge both robotic manufacturers and users to find individual gripping solutions in the same frequency and do so efficiently. Additive manufacturing, or 3D printing as it's often known, has enormous potential here. It allows a shift away from the one-size-fits-all strategy and enables production in batch size one.

For this reason, Schmalz has been working intensively with additive manufacturing technology for several years. It's no longer limited to product development, but can also be applied in small series production. For the know-how carrier from the Black Forest, the aim is not only to individualize the geometries, but also to develop gripping systems in a smaller space and with lower weight.

Manual design of a application-specific gripping systems in conventional CAD is anything but trivial.

An experienced designer needs around one working day to manually design such a gripping system. Schmalz is an SME using trinckle and its paramate engine to provide its customers with an intuitive engineering tool.

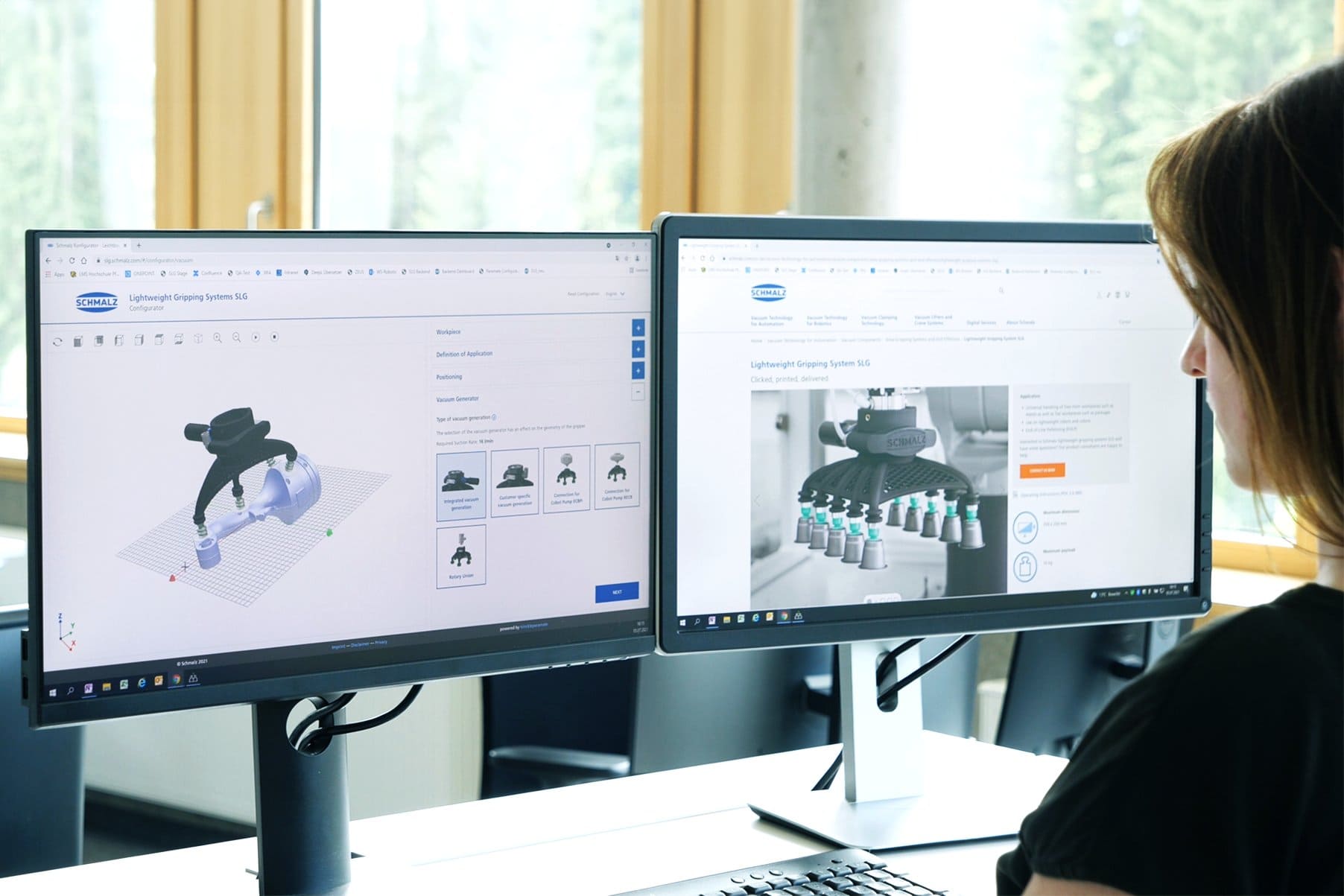

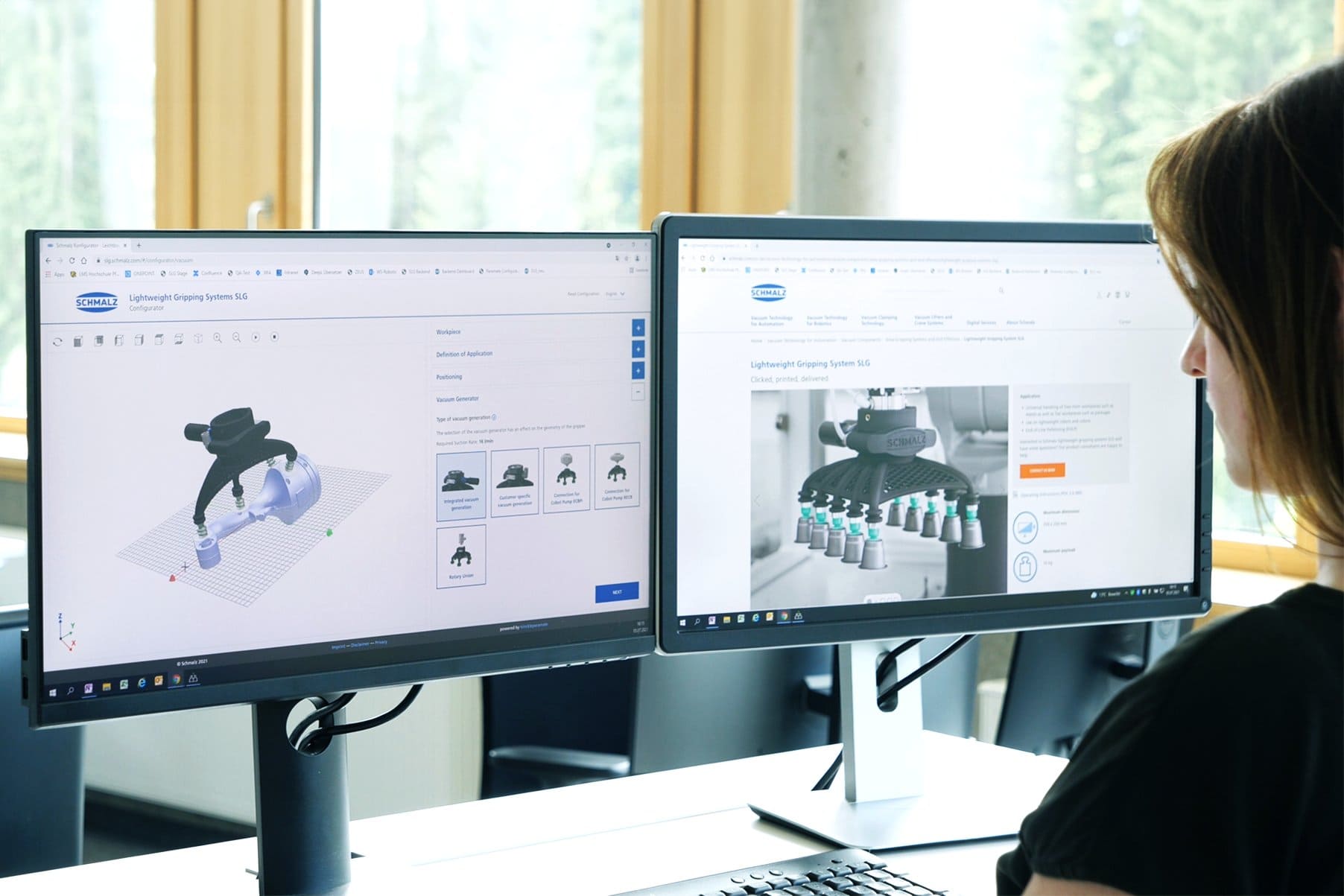

trinckle developed a web application for Schmalz based on its cloud technology paramate, in which users can configure a vacuum gripping system quickly, individually and without special previous knowledge.

This is embedded on the Schmalz website, so Schmalz employees and customers worldwide can access it at any time.

“We made a well-considered decision to work with trinckle because the team of the Berlin-based software company provides a great deal of expertise in 3D printing and automated design. In combination with our in-depth knowledge about gripping workpieces, this has resulted in a very innovative, digital solution for our customers”

Managing Director, J. Schmalz GmbH

First, the user defines the handling task and specifies individual requirements.

Besides various pre-defined workpieces, it's possible to upload pre-existing digital models - regardless of whether they are cubic, angular or with free-form surfaces.

The user then starts the configuration to design the matching gripper. The tool intuitively guides the user through the various design steps, providing application-specific recommendations on the number, diameter and type of suction cups. The intelligent algorithm takes care of positioning the suction cups. Alternatively, the user can define the position of the suction points in a graphical user interface with just one mouse click.

Finally, the user selects the appropriate flange insert and the desired vacuum generation. Once all components and parameters have been determined, the customer receives a CAD model and the quotation for his gripping solution.

The entire configuration of an application-specific gripping system takes about ten minutes and does not require any expertise in CAD software or DfAM (design for additive manufacturing) best practices. The underlying complexity of the geometry generation is handled by rule-based algorithms.

3D printing technology is key to cost-efficient single-part production within a few days. It also reduces interfering outlines, for example by fully integrating the air duct system. The gripping system can be combined with various vacuum components such as the CobotPump ECBPi or the vacuum switch VSi.

This enables Schmalz to manufacture light, robust grippers quickly, which are suited to the particular application. Adapted to lightweight robots and cobots, the Schmalz solution can hold loads weighing up to ten kilograms.

When combined with new paths in the field of automated design, 3D printing has great potential to streamline a vast range of manufacturing challenges.

trinckle's cloud-based software represents the crucial element for transforming a formerly very cost-intensive manual process into a scalable serial application.